11 November 2022

The industry pioneers

Norwegian salmon producer Bremnes, famous for several well known seafood brands like "SALMA" and "BÖMLO", are now together with AION and Circmar testing innovative, reusable pallets, made from 100% marine plastic waste.

“Our work happens at sea, and we need to take care of the environment we work in” says Norwegian salmon producer Bremnes. Now they are gearing up to be pioneers within circular transportation - one pallet at a time.For generations, fish has been carried across the world's oceans using one-way wooden pallets. Now, it is time for a change.– We have always been industry pioneers, says Simon Nesse Økland with a mixture of pride and humbleness.Since 1937, Bremnes Seashore has been one of Norway’s leading suppliers of farmed salmon. As early adopters of trout and salmon farming, they have developed quality products in high demand across the world. Now the company, based on the west coast of Norway, is gearing up to be pioneers within yet another field, namely circular transportation.UntitledLike many other companies, Bremnes Seashore’s biggest sources of CO2 emissions are feed for the salmon and transportation (source: Bremnes Seashore climate accounting). Since august 2022, they have conducted trials for a new way of transporting their fish. Teaming up with Norwegian companies Circmar and AION, wooden pallets have been supplemented with reusable ones. These new, innovative pallets are produced by upcycling formerly wasted plastic from the fish industry’s own value chain.

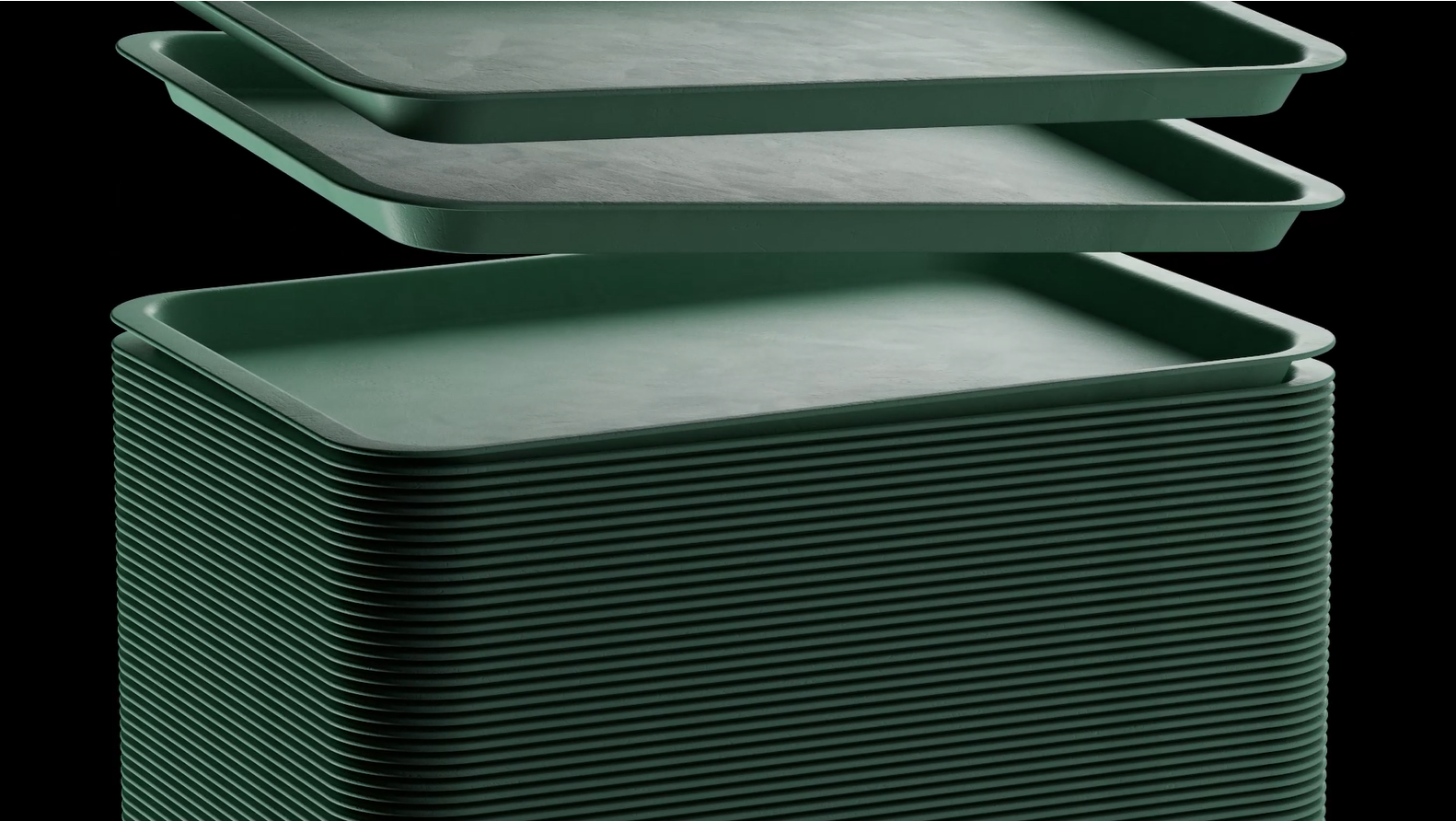

Up-cycled from the fish industry's own value chain

The new pallets, made by AION and put into a circular system by Circmar, are made from 100% single use polypropylene bags carrying fish feed, and are completely traceable. – If the pilot is a success, this is a very interesting case for us. The disadvantage is that we can’t use them on a bigger scale just yet, says Laila Knarvik, Group Technology & Sustainability Manager in the Bremnes Seashore Group.UntitledSpecifically created for the seafood industry, Circmar and their partners are working towards optimizing every part of the value chain. The pallets stack up three times as efficiently as their wooden predecessors, saving space both in storage and on return freight. Strong pallets means less breakage, bigger loads and less food waste.– There are common problems that often occur with wooden pallets, such as breakage and product runoff that soaks into the wood, that simply don’t occur with these reusable ones, says Bremnes ESG Manager, Andreas Moe Larsen.– And then there is the use of wood for disposable pallets, which is a problem in itself, Moe Larsen continues, referring to numbers stating that wooden pallet production in the US alone uses 20-40% of all timber produced today.Today, Bremnes Seashore transports salmon to over fifty countries. In the future, Circmar’s intelligent systems will allow tracking of temperature and pallet location, leaving Bremnes in full control of the journey their products undertake.– We have started testing the system on domestic routes. When we have tested that everything within hygiene, logistics and environmental impact works in our everyday operation, we are ready to expand.UntitledHowever, switching from 100 % traditional wooden pallets to 100 % reusable pallets is not done overnight. The project also has to prove itself to be financially sustainable long term, says Moe Larsen.

You have to get things done

For Bremnes Seashore, this gradual shift is part of a long-term sustainability strategy. As group technology and sustainability manager, Laila Knarvik put it:“Our work happens at sea, and we need to take care of the environment we work in”.– We are constantly working towards having the smallest possible footprint in our entire value chain, while at the same time ensuring quality, she continues. To do this work, Bremnes Seashore is eager to collaborate widely. Both internally in the industry with other breeders and with their suppliers, but also with those who have new solutions and ideas that can push the company further.– This pilot with Circmar and AION fits together with our overall strategy because it means that the pallets will come back, again and again. It means we are able to contribute to the circular economy. An economy which we depend on in order for our company to still be here in the future, says Simon Nesse Økland, Group Communications Officer.UntitledBremnes Seashore is gearing up to lead the way as a pioneer for a more sustainable way to transport fish.– In order to know that this shift will work, we are determined to implement the change throughout our value chain. But in the long term, it must — like everything else we do — be financially sustainable. But you have to start, you have to learn and you have to get things done, concludes Økland.– Everything we do, we do to create a better world for future generations. That is our long term goal. And to do that we need to break out.