The first in a four-part series addressing the practical applications and opportunities for firms considering circular innovation.

For over a century, economic growth has depended on the ability to extract, produce, consume, and dispose. Or, more cynically: take, make, and waste.

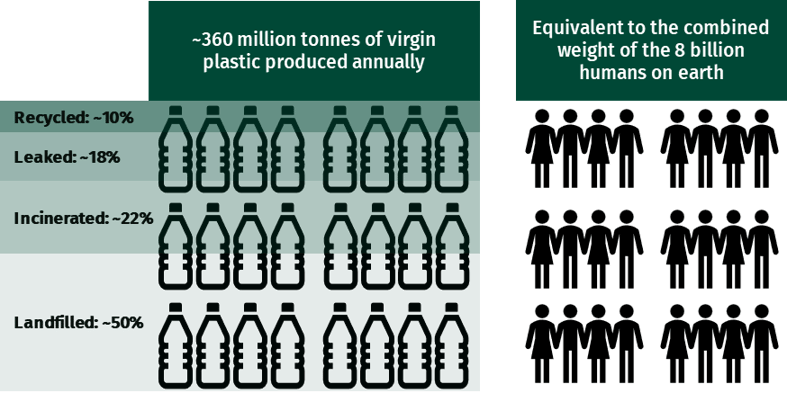

Plastic is a prime example. Cheap, lightweight, versatile and durable – it is the ideal material to form, package, and transport the goods in this linear model. Around 360 million tonnes of virgin plastic is produced each year, equivalent to the combined weight of the global population. Only ~10% of plastic produced is likely to be recycled or re-used—the majority leftover is landfilled, burned or leaked into the surrounding environment.[1]

“The shift to a circular economy—in which value is recovered and waste is designed out—is no longer just an environmental ideal; it’s becoming a strategic necessity”

This extractive approach fuels GDP but leaves a trail of resource depletion, material waste and environmental degradation. The environmental consequences are often the most publicly available to see, but at the heart of this system is a deep commercial inefficiency, also.[1]

As supply chains strain under mounting economic, geopolitical and climate pressures, the shift to a circular economy—in which value is recovered and waste is designed out—is no longer just an environmental ideal; it’s becoming a strategic necessity.[2]

How can it be done?

Firms can unlock major commercial, environmental, and reputational gains by embedding circularity into product design, business models, and supply chains. By designing durable, modular, and repairable products using recycled or renewable materials, companies reduce costs, extend product lifecycles, and boost customer loyalty. Circular business models—like leasing or subscription—create recurring revenue while retaining control over valuable materials through reverse logistics. Extending circularity across the value chain through supplier collaboration, localized production, and digital tools like product passports enhances resilience, reduces waste, and drives smarter, more sustainable operations.

Easier said than done

These notions are neither novel nor controversial. Most businesses would like to be more resource efficient and less impactful. As is often the case when making decisions, the challenge for leaders is ensuring commercial prosperity while protecting the interests of stakeholders and minimising the transition costs.

Procedural or operational change often come from selecting the best initiatives (both strategic and operational) and key results (commercial and environmental) to drive progress towards the desired outcome—in this case, the sustainable growth and futureproofing of the business.

In the next few weeks AION will be explore each of these three topics individually. Check back in on May 26th for a deep dive on the business case for circular products.

[1] https://www.oecd.org/en/topics/plastics.html

[1] https://www.resourcepanel.org/reports/global-resources-outlook

[2] https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en